Hex Meshing of Complex Geometries

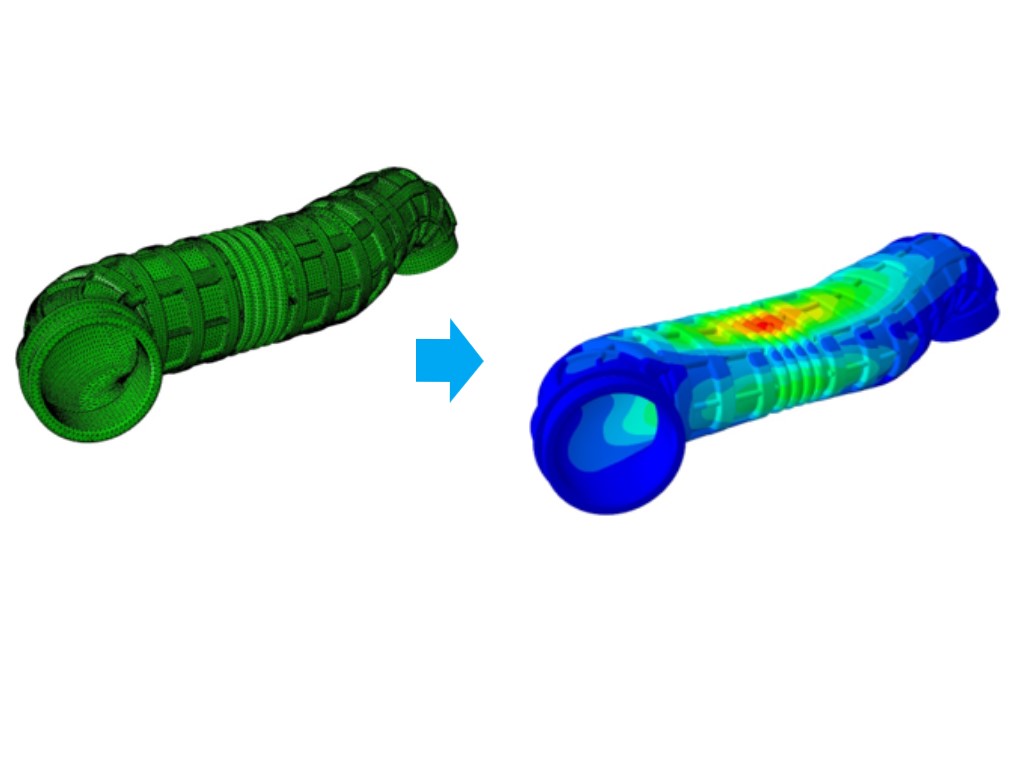

Problem Definition:

Pre-processing in CAE – Meshing is required in Hexahedral element for better part quality.

Description:

Researchers in the world are working on improving on the pre-processing algorithms and techniques for finite element method. The efficiency and accuracy of finite element models are directly dependent on the quality of the underlying meshes in the model. The various quality parameters associated with elements are element size, aspect ratio, skew angle, jacobian, warp and element topology. Element topology means triangular/quadrilateral elements in case of shell meshes and tetrahedral/hexahedral elements in case of solid meshes. Hexahedral elements are very much desired in computational simulations due to better convergence and accuracy. We at AMP Engineering, do the pre-processing in Hexahedral element for better part quality.

Engine Mount Design

Problem Definition:

To design the Engine mount shape meeting NVH (Noise Vibration and Harshness) targets of OEM.

Description:

Rubber bush mountings incorporating annular regions of rubber bonded to rigid metallic inner and outer cylindrical sleeves are used widely throughout the Automotive industry. Engine mount design is very complex process. It involves CAD modelling, benchmarking of Lab results with FEA result. Engine mounts have been vital in automotive for the isolation of Powertrain vibrations and vibrations transferred to chassis from road surface vibrations. Specialized mounts have been designed by AMP Engineering, for Isolation meeting NVH (Noise Vibration and Harshness) targets of three-wheeler, four-wheeler, SUV, LCV, LUV, MUV or MCV manufacturers.

Bump Stopper Design

Problem Definition:

To design the Bump stopper for Isolation meeting NVH (Noise Vibration and Harshness) targets of OEM.

Description:

Bump stopper design is used widely throughout the automotive industry for isolating vibrations in Z direction. Bump stopper design is very complex process. It involves CAD modelling, benchmarking of Lab results with FEA result. Bump stopper has been vital in automotive for the isolation of vibrations transferred to chassis from road surface vibrations. Specialized Bump stopper designs have been designed by AMP Engineering, for Isolation meeting NHV targets of OEMs.

Rubber Hose Design

Problem Definition:

To design the Rubber Hose shape and rib thickness meeting collapse pressure criteria of OEM.

Description:

AMP Engineering provides its customers engineered solutions for molded rubber hose and reinforced formed hoses for applications across many industries. AMP's molded hoses are custom designed for each application factoring in hose path, media being conveyed, pressures or vacuums and environmental factors to ensure performance specifications are met. Rubber Hose design is used widely throughout the automotive industry for flow of fluid. Rubber Hose design is very complex process. It involves CAD modelling, benchmarking of Lab results with FEA result for collapse pressure. Specialized rubber hose designs have been designed by AMP Engineering, meeting collapse pressure criteria of OEMs.