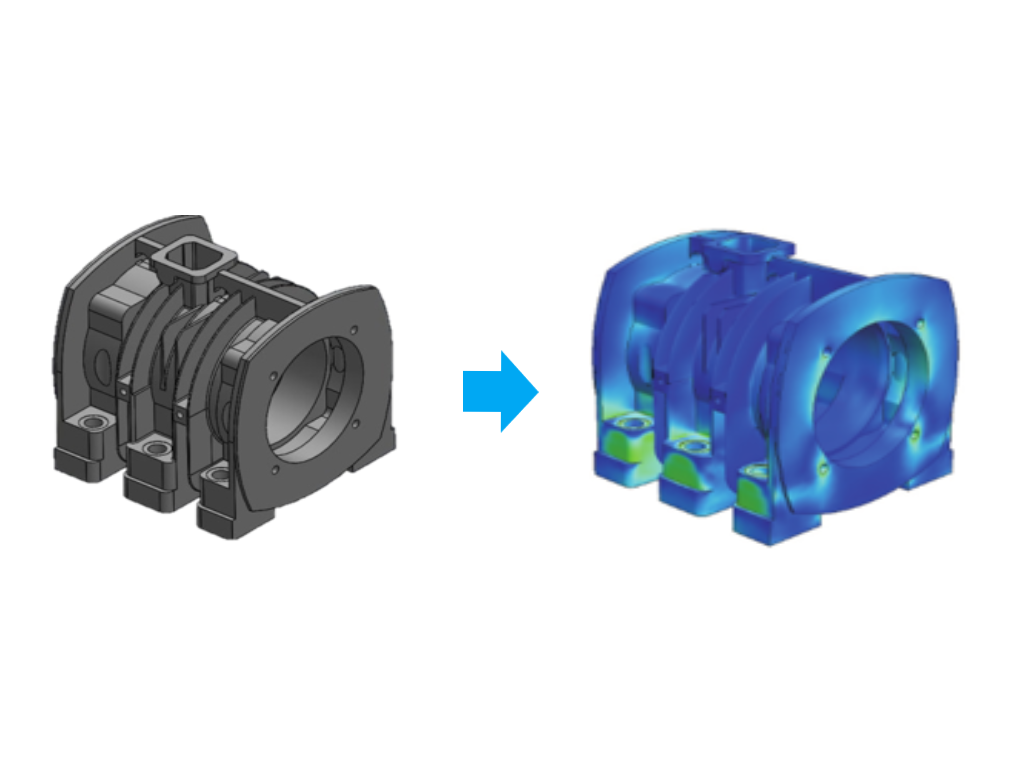

Analysis of Vibratory Motor

Problem Definition:

To carry out static stress analysis of the housing of unbalance vibratory motor in order to study safety of the design, at the same time, study the possibility of material optimization.

Description:

Vibratory motors/Unbalance weight vibration motors are used in material handling equipment such as vibrating screens, conveyors and feeder. The primary components of Unbalance weight vibratory motor are a stator, a rotor (or a shaft), eccentric disc (Unbalanced weight), rotor bearings, bearing housings, and a main housing encompassing all the components (both electrical and mechanical) and fitting arrangements. Upon the passage of electric current, rotor starts rotating. Unbalanced weights are mounted on both side of rotor creating centrifugal force. This centrifugal force, which the motor produces, set the vibrating equipment (table, shuttering, form, conveyor through) and the material (for example concrete) into vibration. The project consisit of static stress analysis of vibratory motor in order to study the stress pattern in the design, using which it can be decided the addition or subtraction of material in main housing. The correlation between lab results and CAE results of inducing stress values were more than 85%.

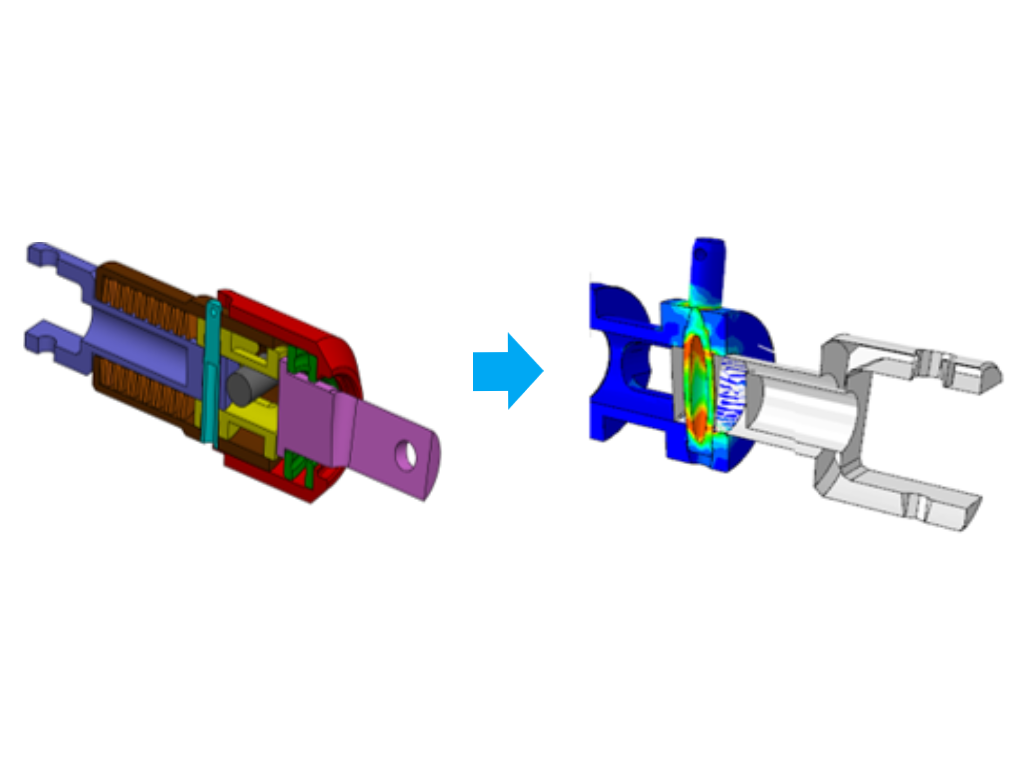

Analysis of Ground Test Rig of Defense Aircraft

Problem Definition:

To carry out stress analysis of shear pin of shear pin holder assembly. Induced stress and critial area of failuere are predicted using Finite Element Analysis (FEA).

Description:

Shear pin holder assembly is a subsystem of ground testing rig. Shear pin holder assembly is used in arrestor barrier in defence aircrafts. The project consisit of FEA of shear pin to predict the induced stress and critial area of failure. The correlation between lab results and CAE results of inducing stress values were more than 92%.

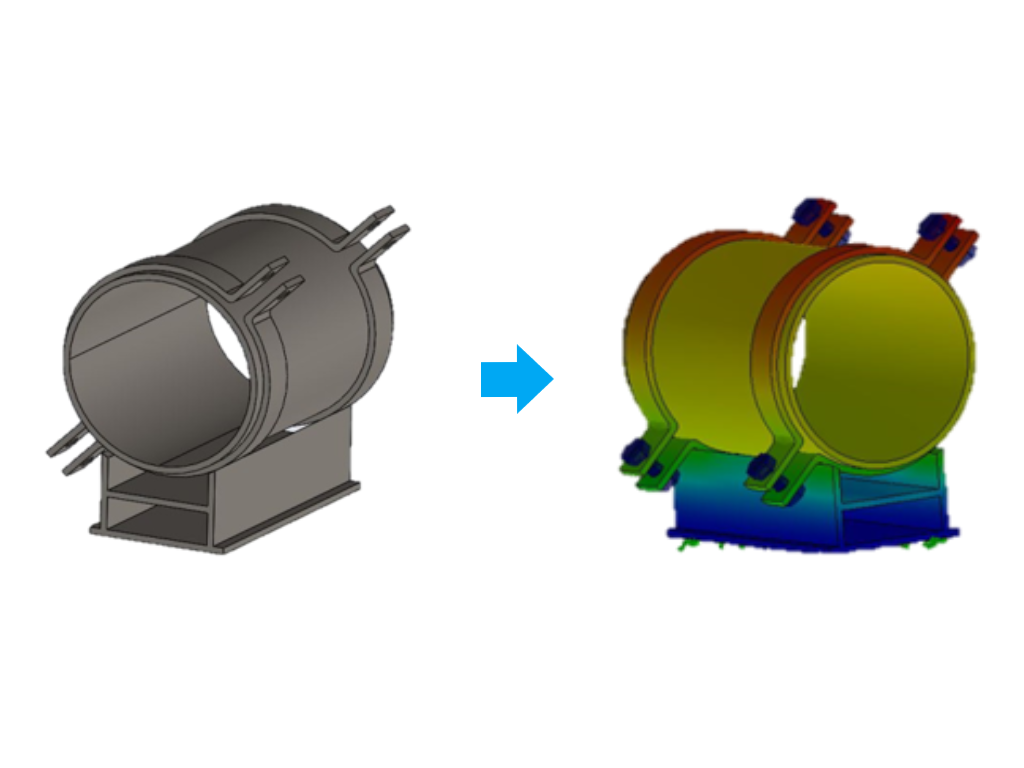

Analysis of Clamp of 1.2m diameter Pipe

Problem Definition:

Design the bolted pipe clamp for given load conditions using Finite Element Analysis.

Description:

Process & Petrochemical Industry uses pipes having diameter of 1.2 m. The dead weight of 20KN was acting on clamp. The maximum lateral force acting on the clamp was 60KN. The project consists of tress analysis of bolted pipe clamp using Finite Element Analysis. The correlation between lab results and CAE results of inducing stress values were more than 85%.

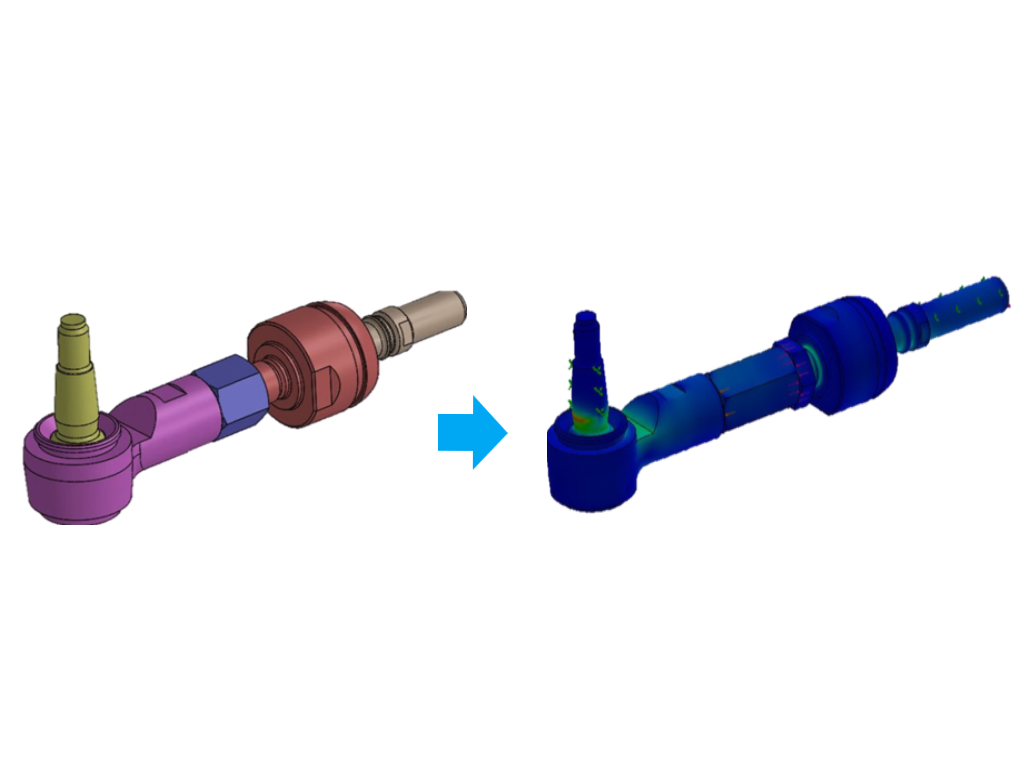

Analysis of Tie Rod End

Problem Definition:

To carry out stress analysis of tie rod end assembly. Induced stress and critial area of failuere are predicted using Finite Element Analysis (FEA).

Description:

Tie rod end is a subsystem of steering system. Ball pin, socket and rubber boot are critial parts of assembly. The project consisit of FEA of Tie rod end to predict the induced stress and critial area of failure. The correlation between lab results and CAE results of inducing stress values were more than 95%.