Rapid Prototyping Simulator

Problem Definition:

To develop the Rapid Prototyping simulator, which can estimates the functional performance parameters of Rapid Prototyping (RP) Parts manufactured by Selective Laser Sintering (SLS) Rapid Prototyping (RP) process.

Description:

Rapid prototyping simulator simulates Selective Laser Sintering (SLS) Rapid Prototyping (RP) process. It simulates the fabrication of the part layer by layer and estimates the performance of the process in terms of its functional parameters. In addition, it facilitates the virtual visualization of the fabrication process. Part quality is computed in terms of the deviation of the fabricated part contour from its nominal shape. Volume of powder required is estimated from the Drexel shape data while the part build time is estimated from the hatch data for each layer. Simulator predicts shrinkage produced in the part for the chosen process parameters. Rapid prototyping simulator gives the output in report format.

Engine Mount Weight & 16 Degree of Freedom (DoF) Calculator

Problem Definition:

To develop the Engine mount calculator, that optimizes the mount positions and orientations as per Torque Roll Axis (TRA) and 16 Degree of Freedom (DoF) requirements of Original Equioment manufacturer (OEM).

Description:

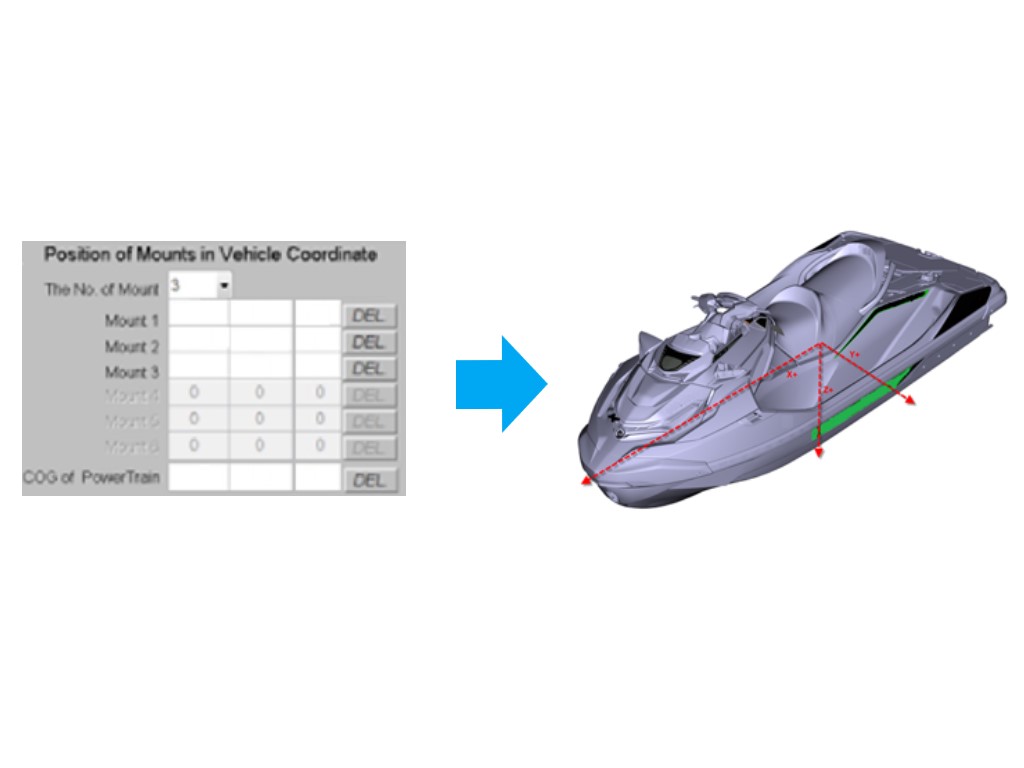

Motor mounts (engine mounts) are used to connect a powertrain to the car frame. Motor mounts are made of rubber and metal. The metal bracket is connected to the powertrain on one side and to the frame on the other side. Isolation is provided by rubber.

3 Mount/4 Mount systems are used for powertrain vibration isolation. Position of mounts, orientation of mounts, dead weight acting of mounts are important parameters for isolating powertrain vibrations. The developed calculator optimizes the mount positions and orientations as per Torque Roll Axis (TRA) and 16 Degree of Freedom (DoF) requirements of Original Equioment manufacturer (OEM).